Model Building Tips

General Building Tips

Cutting Out Printed Wood Parts

by Allan P. WeismanHere is a tip about cutting out small parts that might crack into tiny hard to reglue pieces, such as the small fingers of balsa wood left after cutting out stringer slots. Before cutting use rubber cement to paste some heavy Kraft paper on the back of the printed wood. The Kraft paper will hold all the little pieces in place since the paper has no grain to split. Then later on if there is a split in the wood rub a very thin layer of rubber cement over the front of the split part after cutting. When the cement is dry, peal the paper off the back of the wood, and gently rub with your finger to remove the rubber cement residue. This adds very little weight to the model, but a lot of extra strength.

Trace the parts on the printed wood prior to cutting them out, in

this way you will have a pattern for a Extra part should you

make a cutting error. Another easy way to do this would be to photocopy

the printed wood to make your patterns.

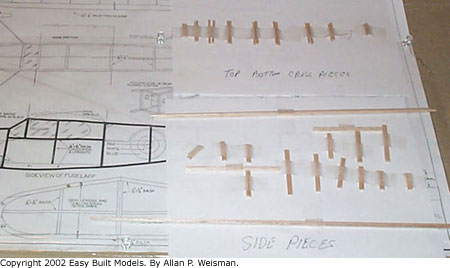

While you are cutting all the fuselage pieces out, some pieces can get lost or destroyed, but fortunately there is a way to keep all the little pieces of strip wood safe from getting lost and in some semblance of order. All that is needed is a sheet of paper, and a roll of double sided tape. Hold the paper sideways, then put a strip of tape across the page near the bottom. You can stick your fuselage-bottom longerons on this strip. Now tape another strip a little farther up the piece of paper, on this you can put the extra uprights from the cabin area. Make another strip for the top-longerons, and then one final strip for the top and bottom cross pieces. Now you have all the strip wood pieces safe from getting lost. If you put them on in order to build the model it makes things a lot easier. This same system can be used anywhere you cut parts prior to construction.

Sanding

Get some spruce sticks of various thicknesses, 1/16, 3/32, 1/8,

3/8, etc. Cut the sticks into 6" lengths then glue different grades

of sand paper on the edges of the sticks. You now have a set of

sander blocks to use on the inside of stringer slots. Sanding blocks

can also be made by gluing sand paper to various sized dowels and

lumber trim shapes such as half round, quarter round etc. for sanding

hard to reach places like the formers between stringers.

Inexpensive sanding sticks can be bought at the local cosmetic department of any of the chain stores. They are inexpensive, can be cut to any shape and come in different grits. The clerk will probably know them as emery boards or nail files. - Dick LeClair

Building Methods

When building a half shell fuselage usually only one side view is shown on the plan. One side is built over the plan, and the other side is built on the first side this can cause a lot of misalignment when gluing the very small areas of the left, and right formers together. These problems can be avoided very easily. The steps to do this are simple.

1) Make a duplicate set of center pieces that the half formers

are glued to.

2) If necessary enlarge the notch in the half former that goes

over the center pieces.

3) Build one half of the fuselage as usual using a triangle to

insure that the half formers are trued up at a proper 90 degree

angle to the building board.

4) Turn plan over, and rub a light coating of cooking oil over

the back of the plan in the area of the fuselage side view. This

will make the plan translucent so that the other half can be built

directly over the plan as the first half was.

5) Glue the 2 sides together along the wide center pieces this

gives you a large glue area, and you can use V notched wood, or

spring clothes pins to hold the 2 halves together as the glue

dries.

Allan P. Weisman

I build all models on a plate of glass, such as that used for a picture, or one cut by a shop. I put the plan underneath the glass. The model is then built as normal on top of the glass, and the pieces held in place with masking tape. This ensures all parts and components are perfectly flat, as well as providing a better work area. Excess glue, paint, and other droppings are easily cleaned with a razor blade or Windex. - Rick Krakoff

Here is another way to build both sides of half shell fuselages over the plan. Most models of this type build with a right side, and a left side. one side is built over the plan, the other is built in the air, which means one side can be perfectly aligned, the other might be built with warps. There are some models such as the Easy Built Gremlin which are built as top, and bottom. This type of construction allows you to build both halves over the plans. Converting the side built to top, and bottom built is not difficult. Simply glue the half formers together on a flat surface. Then locate the center side stringer notch (one that goes from nose to tail). Cut the formers apart across the center of this notch, enlarge the notch to take a full stringer in both halves. Now you can build the top half over the plan top view, using triangles to keep everything properly aligned. When it is dry, take it off the plan, and build the bottom half over the top view, using triangles to keep proper alignment. The completed halves can now be joined, completing the construction. If you need small building triangles, take a strip of balsa 1/4" thick, and 1" wide, now use a miter box and razor saw to cut out as many triangles as you need. They can be pinned to your building board where needed.

It should be noted that this technique will make the model slightly heavier but may make it easier for some builders to get that straight and true fuselage. - Allan P. Weisman

When adding wheels to the landing gear wire, you will need to

use retainers to keep them from falling off. The usual choices

are:

A) Wrap soft wire around the landing gear wire and fix with solder.

This adds weight, and may imbalance the model causing unwanted

turns in flight.

B) Wrap heavy thread around the landing gear wire and fix with

glue. This adds less weight than wire, but may also cause imbalance.

C) Build up a layer of glue on the ends of the landing gear wire.

Unless exactly the same weight of glue is used on both sides,

imbalance may occur.

D) Bend the ends of the landing gear wire. This does not affect

in any way but one, it doesn't look good esthetically.

Here is a great no-cost alternative wheel retainer that adds very little weight, causes no imbalance, and is virtually invisible. There is always a bit of celluloid left over after cutting out the window patterns for a model (other plastics can be used as well), use a paper hole puncher to easily make small round, invisible retainers of equal size. Now use a pin to make a hole that is less than the diameter of the landing gear wire in each of the retainers. All that remains is simply to force the plastic onto the ends of the wire. Friction will hold the plastic retainers in place, and they are invisible. - Allan P. Weisman

De-Thermalizer - The simplest way to deal with a kick-up stab DT, would be to extend the fuselage back to the rear edge of the rudder, then build a subrudder to match the plan, and let the stab with upper portion of the rudder attached rest on the top of the fuselage. On my Miss Canada Senior, I ended the fuselage where the plan shows and after building the rudder per the plan, I simply cut it in two pieces on a line level with the bottom of the stab line, added a couple of reinforcements on each side of the cut, glued the upper rudder portion to the stab and the lower portion to the bottom of the fuselage extending aft as shown on the plan. You'll need some better support than shown on the plan for the sub-rudder. I also widened the fuselage about 1/8" at the point where the rear motor is located to make a blast tube easier to insert. - George White

Gang Cutting Ribs from Template

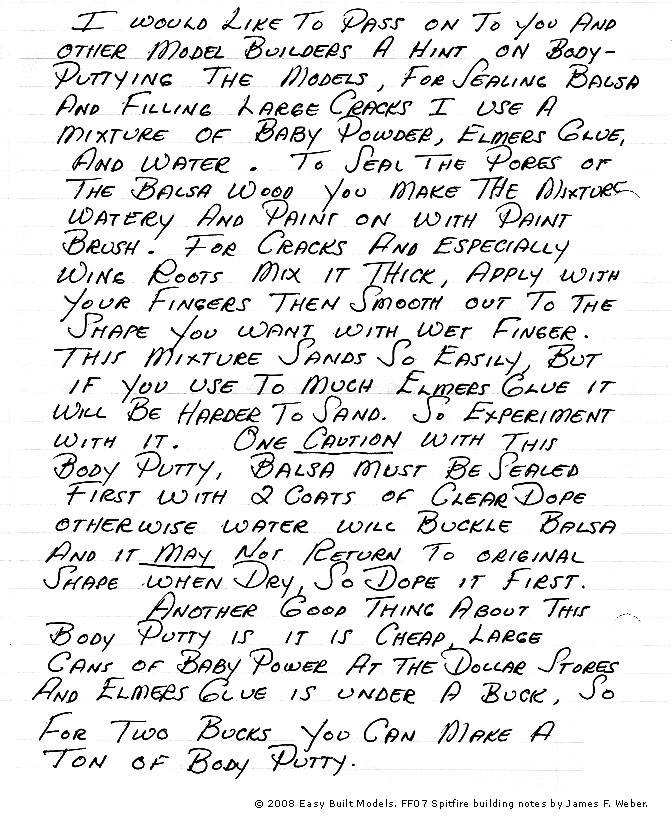

Wood Putty for Balsa

Gluing Up Your Model

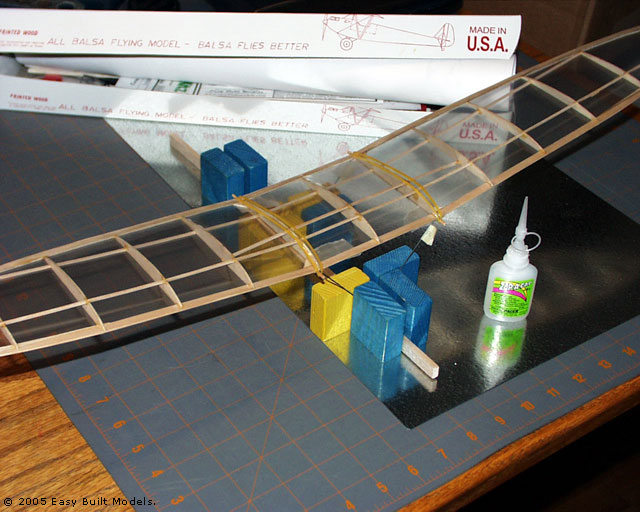

There is an easy way to insure that wing ribs, and fuselage clam shell type construction formers are held at a 90 degree angle to the building board while the glue dries. All that is needed is a supply of triangles that can be pinned on either side of the rib, or former. To make these triangles you will need various widths of 1/8" strip wood, a razor saw, and a miter box. For wing ribs I recommend 1/8" X 3/4", and for fuselage formers I recommend 1/8" X 1", and 1/8" X 2". Simply measure along the length of the wood, and mark off sections equal to the height of the strip. Thus you will have marked off 3/4" squares on the 3/4" wood, 1" squares on the 1" wood, 2" squares on the 2" wood. Then use the miter box and razor saw to cut out a supply of 45 degree right triangles. Now all you have to do is pin 2 triangles on each side of the rib or former to hold the part at a perfect 90 degree angle till the glue dries. Please note because of the dihedral on some models it is necessary to glue the wing root ribs at an angle. In these cases simply calculate the proper angle, and use a protractor to transfer it to the triangles used to hold that rib in place.

When building a model, there is always the extra glue that has hardened around a joint and has to be removed. This can be minimized by using flat toothpicks as glue sticks. Instead of squeezing large gobs of glue onto the parts, apply the glue to the end of a flat toothpick and then transfer it to the parts. Not only does this permit you to apply the glue where it is needed and no where else, it also saves the cost of all the wasted glue, and the time and trouble of removing the excess later. - Allan P. Weisman

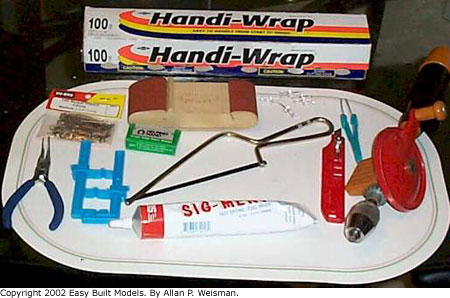

Tools for the Model Builder

Here is a picture of the basic tools required to build the framework of a model. Please note that the items shown are a representative. In other words the X-Acto Jr. knife shown might just as well be a #1 knife, and the saw shown might be a coping saw. This picture is merely to give the new modeler an idea of what is needed.

The items shown are:

PLASTIC WRAP: To cover and protect plans.

T-PINS: To pin parts down.

SANDING BLOCK: For clean up work, final shaping of nose block, and

preparing for finishing.

PUSH PINS: To pin plan and plastic wrap to building board.

RAZOR BLADES: For cutting wood in straight lines.

SAW: For rough shaping of nose blocks.

TWEEZERS: For handling small parts.

MODELING KNIFE: For cutting curved surfaces.

HAND DRILL: For drilling out hole in nose block for prop bearing.

PLIERS: For shaping landing gear wire.

CLAMPS: For holding parts together while glue dries.

GLUE: For gluing parts together.

- Allan P. Weisman

Covering Your Plane With Tissue

Making the panel lines on models can be difficult if you don't know

how to do it. Here are some of the easiest ways to do it:

Some people like using pens and pencils to draw the panel lines.

Round fuselages are the easiest to deal with, wind up the motor,

hold the pen firmly extended, and while holding the prop carefully

bring the spinning fuselage up against the pen. Just kidding, I

found making a couple of plastic straight edges from .005 plastic

to work good. Some of these are short, some long, some with rounded

or square ends. Clear is nice because it allows you to pick up your

location. Get a very soft artist pencil, these leave a nice dark

mark without damaging the tissue, use these for your reference points

when you are ready for inking.

Another thing that has worked equally well for me is to enlarge a good, detailed three view to the size of my model. I cut out the various lines and features that I want to mark. Take your copy with the cutouts, make a few extra holes in the copy for catching reference points such as trailing and leading edges on the wing to be marked and then fold the paper over the edges. Lightly grip the structure with the pattern over it and start following the lines you cut. This is great for some of the wild WWII landing gear outlines. Sometimes I will make a little tick for continuing a line that will cross over an open space. This will be completed with one of the plastic rules after I remove the copy paper pattern.

And yet another method is using a combination of post-its and 8010 magic removable tape to mask the lines and airbrush your markings on, my favorite, but time doesn't always allow for this.

The easiest and most forgivable that I know of was taught to me by Paul Boyanowski. He would take this adhesive film tape, adhere black tissue to it, cut thin strips, remove the backing and apply. This allows for you to carefully position it as you go along. I modified it by using the glue stick in place of the tape and finish with a layer of clear Krylon.

To each his own but I rarely, as in glues, use only one technique on a model. A final spray of the Krylon clear provides an even overall appearance. Have fun. - Dave Niedzielski

Rubber Motors

Hi, I'll try to give you a real short version of my Hi Gumbandery piece that appeared in both the Flying Aces and the Famous Cloudbusters newsletter called "Twice Twisting Tan II".

Here goes, Once you've decided the cross section you need, make up a motor that is twice as long and has one half the section. If it's a small motor, 1 or 2 strands, tie a 1" loop at each end of the big loop. If it's a larger motor, serve a small loop at each end with a small rubber band wrapping. Then, lube it. Then secure one end and put in 4-5 turns per inch winding in the same, I repeat the same, direction you wind in when flying. Then, bring the two small loops together and serve them together with a small rubber band. Then, "milk" the doubled over rubber until it forms into a straight braided motor. The two smaller loops will be relaxed, not twisted and will be easy to work with. On a smaller motor you can then insert a 1/2" piece of a large plastic straw into the doubled over end which would go into the rear of the model, the rear motor peg goes through the straw. On larger motors use a section from a ball point pen cap, it's stronger. You can use a motor 2 1/2 times the prop hook/rear motor peg distance with this method. Stretch wind in your turns, then just hold the model and be amazed as the rubber motor unwinds and bunches up in a series of twisted knots. When all the torque turns are out of the model, when the prop stops turning, there will still be considerable tension on the motor. It will not shift around and mess up the CG. No fancy stops needed. If you are free wheeling, you'll need a latch type free wheeler as the simple spiral catch won't work, there is too much tension for it. After the motor has unwound, you can grab the nose block and pull it forward and the bunched up motor will release about 50 turns and the motor will again hang out past the front of the model. Thank Andy MacIsaac and Don Srull for this great and simple method of braiding. No more need to have a tight large section motor peg to peg. You can extend it way beyond the length of the fuselage, calm down the climb, and extend the motor run, especially on unlimited's and old timers. Have fun. - Ralph D. Kuenz

Making Your Own Propellers

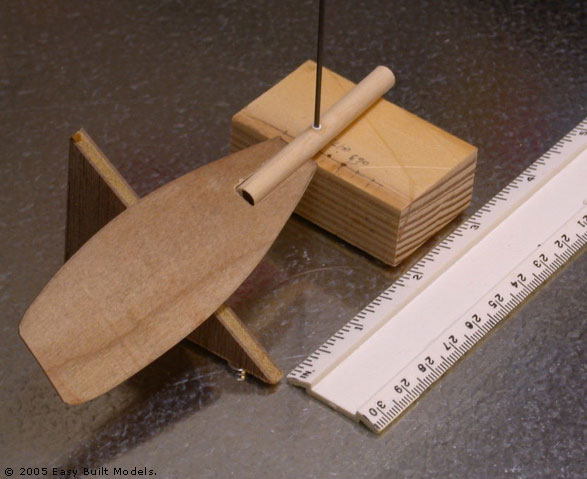

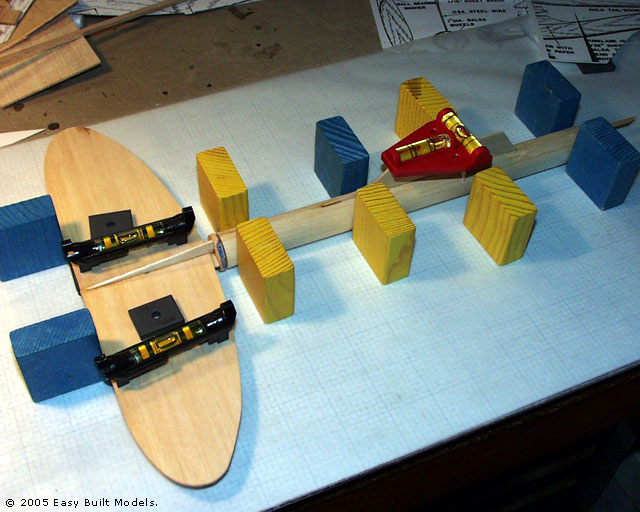

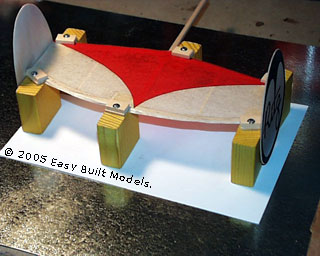

George White made the jigs seen below so that he could make his own propellers.

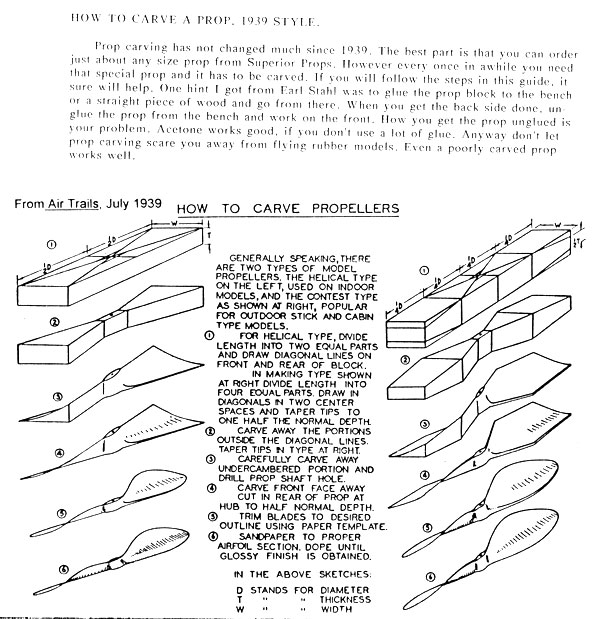

Here is the old fashioned way to carve a propeller. Some still do it this way, particularly when building a model for display.

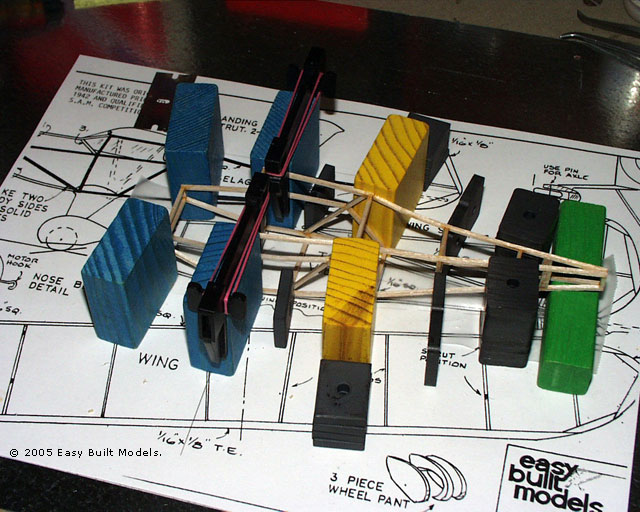

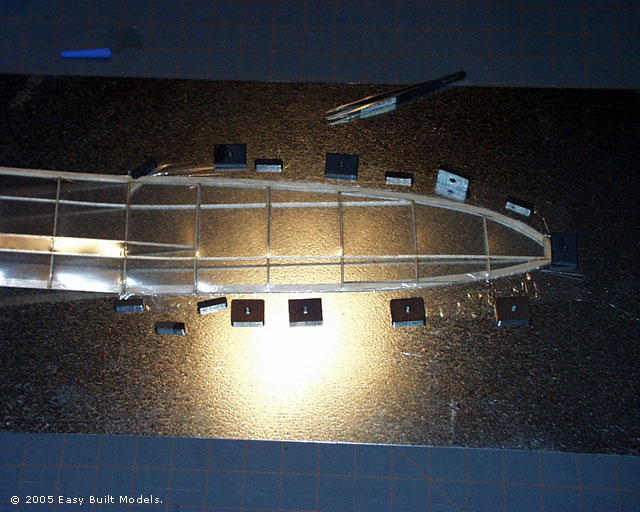

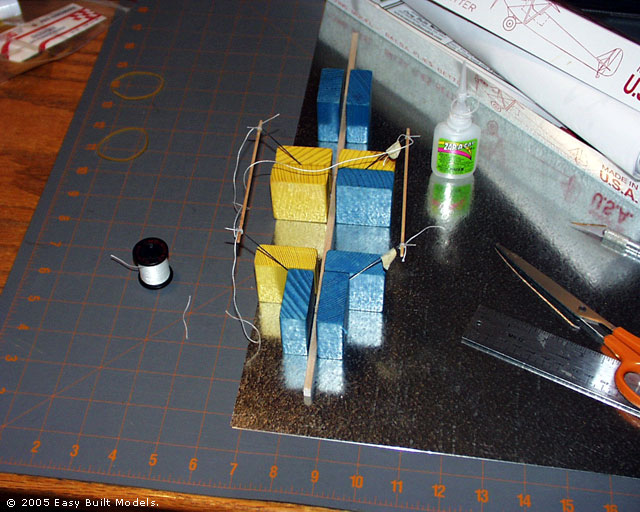

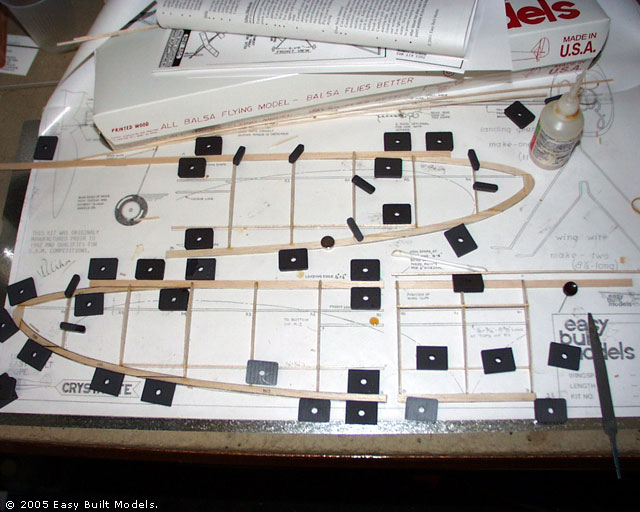

Building with a Magnetic Building Board and Magnets

Photos from Steve Kranish demonstrating some ways to build with magnets.

Click here for a review of the MagnaBoard™

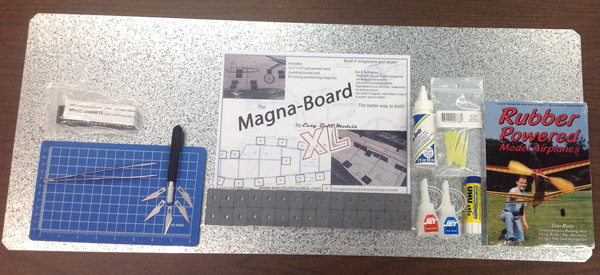

Building Set for Rubber Power

Includes a hobby knife, 5 blades, straight point tweezers, 5.5" x 9" Self Healing Cutting Mat, Jet Instant glue, Jet Super glue, Jet Tips, glue stick, canopy glue/tacky glue, MagnaBoard XL™ set, Minus Magnets 20 pack, and Rubber Powered Model Airplanes book. Save 25% off individually priced items! There is a limit of 2 sets per order.

item B329 Price: $79.95

Building Set

Excludes the book on rubber power and the glue stick. Includes a hobby knife, 5 blades, straight point tweezers, 5.5" x 9" Self Healing Cutting Mat, Jet Instant glue, Jet Super glue, Jet Tips, canopy glue/tacky glue, MagnaBoard XL™ set, and Minus Magnets 20 pack. Save 25% off individually priced items! There is a limit of 2 sets per order.

item B332 Price: $66.95

Advanced Tool Set

Includes Sanding Stick with 120, 240, 320, 400, and 600 grit belts, Pull Saw Blade, K5 Heavy Duty Knife with beveled blade, Narrow Keyhole Saw Blades 5 pack, Curved Tip Tweezers, 1/16" Ball Tip Burnisher, Jewelers Needle Point Awl, Steel Ruler 6" x 1" with drill gauge, 15 piece drill set (1.05mm - 2mm). Save 30% off individually priced items!

item B330 Price: $45.99

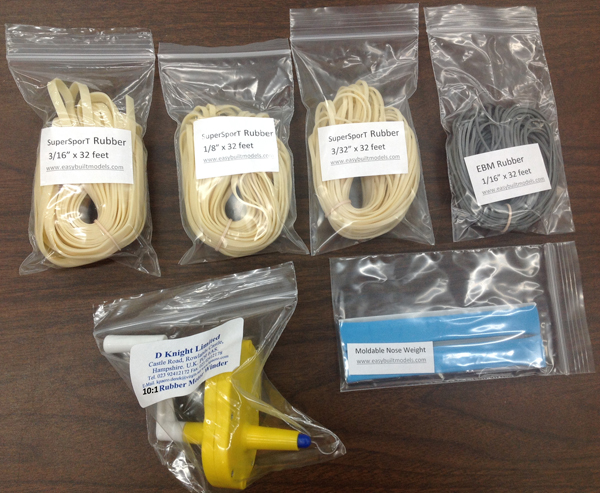

Flight Pack for Rubber Power

Includes a 10:1 winder, moldable nose weight, FAI SuperSport rubber 32 feet each 3/32", 1/8", and 3/16" and 32 feet EBM 1/16" rubber. Save 23% off individually priced items!

item B331 Price: $34.95